KPIs to drive behaviour and organisational performance

A few years back we were asked by a client for advice on their plans to introduce a new variable compensation system that relates to safety performance. The previous bonus system was only connected to their Lost Time Injuries (LTI) performance.

Identifying the correct indicators and reward system to improve safety performance

A few years back we were asked by a client for advice on their plans to introduce a new variable compensation system that relates to safety performance.

The previous bonus system was only connected to their Lost Time Injuries (LTI) performance. That kind of system has two potential drawbacks for companies that do not yet have a mature safety performance. First, when a bonus system is entirely based on LTI or other lagging indicators, it can discourage reporting and/or make people come to work when they should stay at home. The second problem with basing rewards on LTIs is that it often does not achieve the desirable result, simply because people fail to see how this translates into daily action.

The company realised it needed to use a balanced mix of leading and lagging indicators. The new draft system that we were able to review included a combination of both. The main lagging indicator for the company was still LTI, and zero LTIs were the non-negotiable condition for employees to be eligible for the bonus system.

The bonus amount, though, would depend on several leading indicators, such as:

- 6S* performance

- Execution of safety action plans

- Organisation of safety briefings

- Reporting of near misses

- Execution of safety audits

* 6S - Sort, Set in order, Shine, Standardise, Sustain, with Safety embedded

Making the most of KPIs through an integrated performance management system

These key performance indicators (KPIs) look good at first sight, but let us look at performance management in general and what it is meant to achieve.

The old saying ‘what interests my boss, fascinates me’ is of course still valid, but a strong performance management system consists of much more than only producing a long list of KPIs.

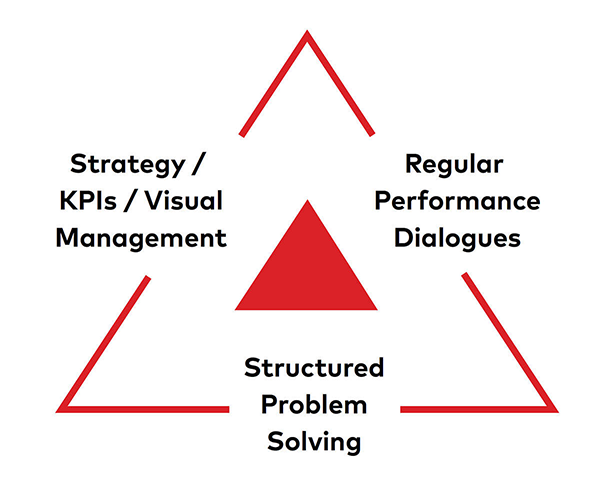

The performance management triangle includes:

It all starts with defining your vision and strategy; not at a high level, but at a more tangible one which allows each level of the organisation to make the right choices on a daily basis. How often do we see a vision statement on the wall, where the company name can be replaced with that of another company: “We want to be the safest, highest quality, lowest cost producer of … while delighting our customers with worldclass delivery and continuous innovation, delivered by the most engaged employees”?

It is essential to take a step back and rethink the actual strategy. In which areas do the company really need to excel, and in which can it accept parity? A clear, prioritised strategy enables an organisation to push decisions to the lowest possible level, because people at that level understand the ultimate priorities.

Once the company has a clear strategy, how do we then translate it into meaningful KPIs for every level of the organisation? How will the shop floor worker know that at the end of their shift they have contributed to the business goals? A high-level KPI, such as LTI, will not do the trick. Organisations need to think about how it can be translated into one or more meaningful KPIs that are tangible on the shop floor.

Visual display and visual management of meaningful and real-time KPIs for each department enables regular performance dialogues. The ultimate questions should be: How can you get the rhythm of the whole organisation ‘in sync’ to achieve these business results? How can the shift changeover discussion be escalated to a daily cross-functional review between operations, maintenance and engineering? Which topics need to be put forward to the weekly or monthly longer-term management processes?

The third leg of strong performance management is problem-solving at different levels. We are all familiar with long lists of action items, or a long backlog in maintenance departments, because every deviation is referred to another department, buried in a work order or on a project list. Highly effective problem-solving uses the capabilities of the entire organisation, by moving the majority of actions to the lowest level possible (1st tier). That may require a change in company culture towards a more independent or interdependent organisation, so operators, mechanics, lab technicians and customer service representatives not only feel permitted, but positively encouraged, to solve the majority of problems themselves, right away. Many operators know their process and equipment so well that they hear or sense when something deviates from the norm. Companies should not ignore that long-established familiarity with the process or equipment, but should instead increase the technical and problemsolving skills at their prime value creation activity, which is, in most cases, the operations shop floor. Of course, there will always be issues that need the involvement and expertise of different departments, but that should not be the initial response. This should be reserved for 2nd tier problem-solving that brings together the right people to solve an issue in the short term. And some more fundamental problems may need to be solved in longer-term projects, or value accelerators, led by a continuous improvement or a project leader.

Visual display and visual management of meaningful and real-time KPIs for each department enable regular performance dialogues.

At dss+, Safety Perception Survey™ results, are used as a tool to probe and uncover safety culture performance issues that might otherwise go unnoticed and which could adversely affect our safety performance. They offer a proven and effective solution to pinpoint the “safety mindset” within the organisation and allow us to proactively address issues before an incident occurs.

It should not be forgotten, that other KPIs such as the timely investigation of incidents, the timely execution of action items, and date changes to action items should also be used. We suggest adding this last one, because we noticed that people were changing execution dates, often for good reasons (waiting for an investment or if a further investigation is needed). The companies should be able to control this and therefore increase the approval authority for a date change to a higher level, and begin tracking this KPI. We also support clients with improving idea generation or bottom-up innovation, tapping into the problemsolving capabilities of the entire organisation. We therefore suggest to also measure the generation of ideas and their actual implementation. The aim is to move execution to the lowest possible level, to avoid a long list of capital projects or maintenance work orders.

Another leading indicator is a “Safety Culture Pulse Check”. This consists of a targeted short list of questions which asks people how they feel about HSE, how leaders are behaving, and how they are responding to feedback from the teams. This comes as an addition to our more extensive Safety Perception Survey™ that takes place every other year. We suggest adding the pulse check to keep safety perception alive and happening at regular intervals (monthly, quarterly). The pulse check is most powerful when the dialogue is more important than the recorded results. Therefore, it is key to process the results in the natural work teams right away.

It is possible to combine some of these lagging indicators into a traffic light that is positioned at different entrances, so people immediately can see how the company is doing. It is a type of safety energy index, providing sites with feedback on their risk level and awareness. The traffic lights can also be used to keep people alert at times of great distraction, such as big maintenance activities, turnarounds or a high contractor ratio on-site.

The aim is to keep KPIs fresh and effective. Instead of just continuing to use the same KPIs as before, it is important to monitor performance against them. If all action items are closed, if your dashboard shows green all the time, that is the time to be suspicious, not the time to relax and be complacent. It is precisely the moment to ask yourself what is going on and whether you should be re-evaluating your KPIs and digging deeper.

|

Questions to ask yourself when setting KPIs Let us go back to the initial question from this company: “... can you please advise on these leading indicators for our bonus system?” Before analysing these specific five leading indicators, it is worth taking a step back and asking a few critical questions in order to find out what the organisation can realistically expect to achieve.

The answers to these questions matter. If an organisation is not yet “mature” in its safety performance, it will need to focus on preventing fatalities and serious incidents, as well as high-potential near misses, before introducing a KPI for other more minor near-misses. With increasing maturity, the organisation can select additional KPIs, and react to more subtle signals, as well. In an immature organisation that is just starting with an auditing system, tracking quantity metrics like the execution of the number of audits is a sensible KPI. As the organisation develops in maturity, quality metrics should be introduced, e.g. audit scores and actions completed on time. Once this is under control you can add a further focus on repetitive findings, and make a connection between audit findings and actual incidents. |

Review of the proposed leading indicators

The right KPIs can drive the right behaviour, if other critical elements of a performance management system are incuded, but consequently the wrong KPIs can drive the wrong behaviour.

In essence, HSE compliance and proactive behaviour are a condition of employment, so it can be very tricky to reward people for behaviour that is expected of them in the first place. With all this in mind, here is our response to the leading indicators that the company was considering:

6S performance

It is good to make a connection between 6S and safety, and the Sustain ‘S’ in 6S indicates that it is critical to sustain this at all times. However, adding it as a leading indicator connected to the bonus system might limit the cascading down process. Ideally, you would like employees to own 6S themselves and do the checks/checklists themselves. Incentivising an audit of their own area with a variable compensation system might lead to a biased view.

Implementation of safety action plans

Strong follow-up and a disciplined closure of action items are clear indicators of the operational discipline and the workload in an organisation. However, since most organisations do not use their 1st tier problem-solving capabilities very often, not many action items are really assigned to the shop floor. Action items will mainly be allocated to engineers, supervisors, managers and professionals. And in that case, shop-floor employees might not be able to influence the implementation or closure of those action items.

Organisation of safety briefings

Both organising and attending safety briefings, trainings, toolbox meetings should be mandatory and should therefore not be rewarded additionally.

Reporting of near misses

This is another important indicator of the cultural maturity of an organisation. Mature companies want to ensure they have visibility at the bottom of the safety pyramid, before actual injuries occur. They want people to be more proactive. Sometimes when our dss+ consultants visit a plant, they see damaged warehouse racks and protection bars, and yet there are no reports of any internal traffic incidents.

So, what target should the organisations put on near misses if they want to have a good reflection of reality without driving an excessive amount of reporting; if they want ‘quality’ near misses, capturing those incidents that offer critical opportunities to learn; or if they want to validate that they have captured the ‘right’ pyramid ratio, between recordable injuries and near misses?

A more proactive way of capturing the bottom of the pyramid is to track and reward the number of generated and implemented safety improvement ideas. The same behaviour might be driven with a better KPI. Companies should be asking themselves whether they can track the level of learning in the organisation through the metrics used.

Safety audits

Auditing safety management system is critical, but where should the organisations set the target? Do they focus on the audit score or on the execution of the audit plan? Execution of the audit plan is a straightforward KPI which people should be able to influence.

However, putting a target on the auditing scores can introduce some potential risks. This type of KPI might put pressure on the auditors in a less mature organisation. They will know that the organisation’s variable compensation system will depend on how strict they are; an audit is never fully black and white. Sometimes people have an increased understanding of what a standard really means, and they raise the bar for themselves. Sometimes, the audit score stays flat, because they are seeing it from a different point of view, which is what organisations want to encourage, to constantly raise the bar.

A strong performance management system consists of several elements that need to be integrated to achieve the desired results. KPIs are just one of them.

Conclusion

A strong performance management system consists of several elements that need to be integrated to achieve the desired results. KPIs are just one of them. Organisations can use KPIs to drive behaviour and, in the end, organisational performance, but it is essential to carefully consider what behaviour is desired versus what it is that the existing KPIs actually drive? What could be the unintended consequences?

Although variable compensation system directly linked to HSE KPIs can work, the power of reward and recognition, beyond monetary rewards should also be considered. Maintaining a strong safety culture requires the entire organisation to collaborate. Other recognition initiatives could consist of team awards/team events when reaching a certain milestone, verbal recognition for extraordinary achievements (eg. president’s safety award, safety coins, safety medals) or team rewards for generating improvement ideas.