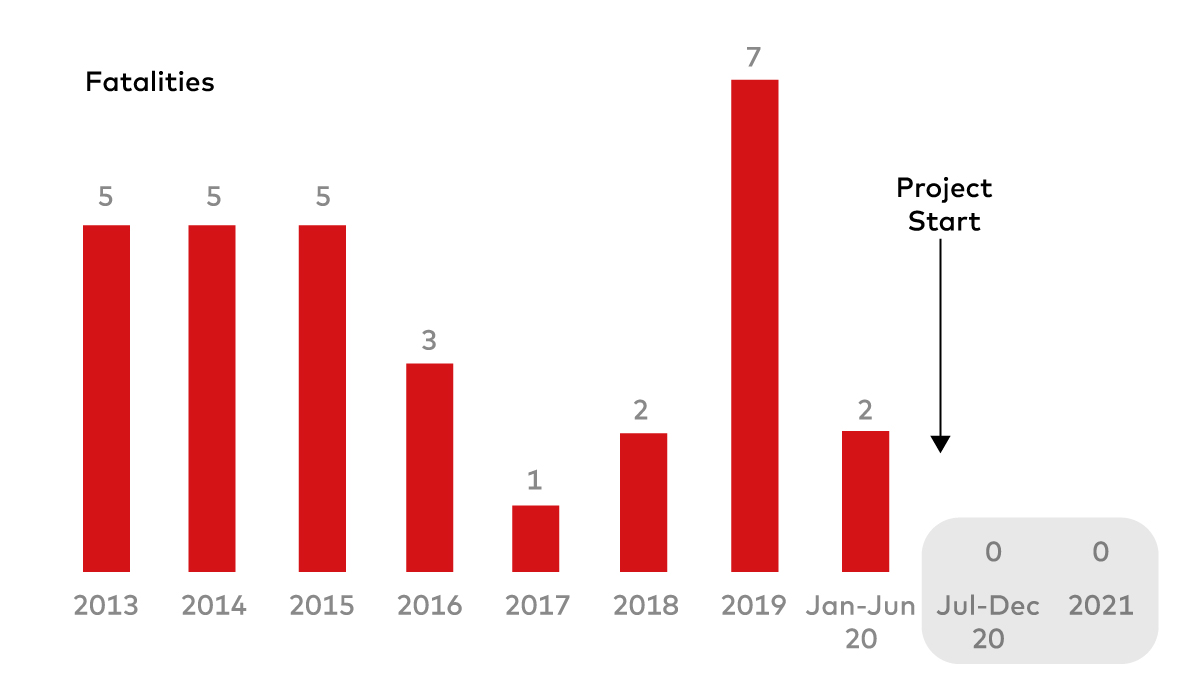

Zero-fatality goal becomes a tin mining reality

One of the world’s largest tin producers, this metal processing client relies on more than 150 artisan mining sites, all spread across islands and often run by community contractors. Although the company set a zero-fatality goal, numbers remained high, putting the firm’s license at risk. Unsure of how to move forward, leadership reached out to dss+ for guidance in improving the safety culture, reducing incidents, and eliminating fatalities.

Challenge

One of the world’s largest tin producers, this metal processing client relies on more than 150 artisan mining sites, all spread across islands and often run by community contractors. Although the company set a zero-fatality goal, numbers remained high, putting the firm’s license at risk. Unsure of how to move forward, leadership reached out to dss+ for guidance in improving the safety culture, reducing incidents, and eliminating fatalities.

dss+ Approach

dss+ developed a three-year program with an immediate focus on containing the 15 most dangerous risks, including as mine pit collapses and falls, drowning, and molten material spillage during handling and lifting. The goal was to generate quick wins, underscoring management’s commitment to change and demonstrating that a zerofatality goal was within reach.

To strengthen the client’s own processes with proven methodologies and best practices, dss+ recommended a comprehensive framework spanning:

- Mindset and behaviour change-recognising that a zero-fatality goal is possible, and that safety is everyone’s personal responsibility

- Capability building around risk mitigation

- Technical models such as a customised risk containment process

- Management processes regarding safety governance, leading indicators and more

This multifaceted effort increased engagement, capability and safety thinking from top leadership to operators. The impact has been dramatic, with zero fatalities in the first 18 months.

Assignment

Reduce incidents and, ultimately, fatalities in a high-risk environment.

Offering

Operational risk transformation consulting, including culture transformation.

Impact

- 0 fatalities for the first time in 15 years

- 60% reduction in risk exposures in first 12 months

- 200 billion Indonesian rupiah (€13 million) estimated cost avoidance per fatality

"As a company oriented to good mining practice, we are grateful that the number of work accidents can be reduced to zero fatalities."

– Company Executive