The Future State of Reliable Utilities

Utility organisations today are confronted with myriad challenges, including ageing infrastructure, expectations of greater reliability at a reduced cost, and coping effectively with uncertainties around changing regulations, weather events and more.

By Ahmad Alhonjol, Willem Nel, Wasim Khoudari at dss⁺

The transmission and distribution industry is further influenced by issues that impact how they move forward with business development, such as:

- Increasing demand on networks

- Reduced system redundancy

- Operating restrictions that limit maintenance outages

- Income tied to installation availability

What’s more, regulatory frameworks often demand strict technical requirements and impose severe penalties for not meeting objectives.

Over the next 20 years, emerging countries will need to swiftly expand power networks to serve growing populations. At the same time, those in developed economies will need to upgrade ageing infrastructure, implement smart grids, and respond to mounting regulatory, customer and technological pressures. To meet demand, by 2035 the world’s transmission and distribution lines will need to increase by more than one-third—to an estimated 94 million kilometres—with an estimated cost of more than $310 billion per year.

Improving Asset Performance Through Maintenance and Reliability

For transmission and distribution systems, HV/MV substations represent complex, critical physical assets that require careful evaluation of maintenance practices with the goal of improving performance and efficiency.

Optimising maintenance is one way to attain these objectives—ultimately increasing reliability and customer satisfaction while meeting demand as economically as possible. Utilities will need to implement new strategies with more effective maintenance techniques and asset management programs in order to better control HV/MV substation equipment conditions and costs. However, any forward-looking maintenance and reliability (M&R) strategy must also consider how best to manage ageing and outdated infrastructure, whether to outsource services and more.

Drawing upon our experience with hundreds of global organisations, dss+ has developed a comprehensive performance management and operating model that significantly and sustainably impacts utility asset availability, operational effectiveness and cost. Applying deep technical and organisational transformation knowledge, this method reaches beyond strategy and core processes to leverage often ignored yet essential foundational factors and functions that we believe are vital to success.

Comprehensive transformation requires a comprehensive view

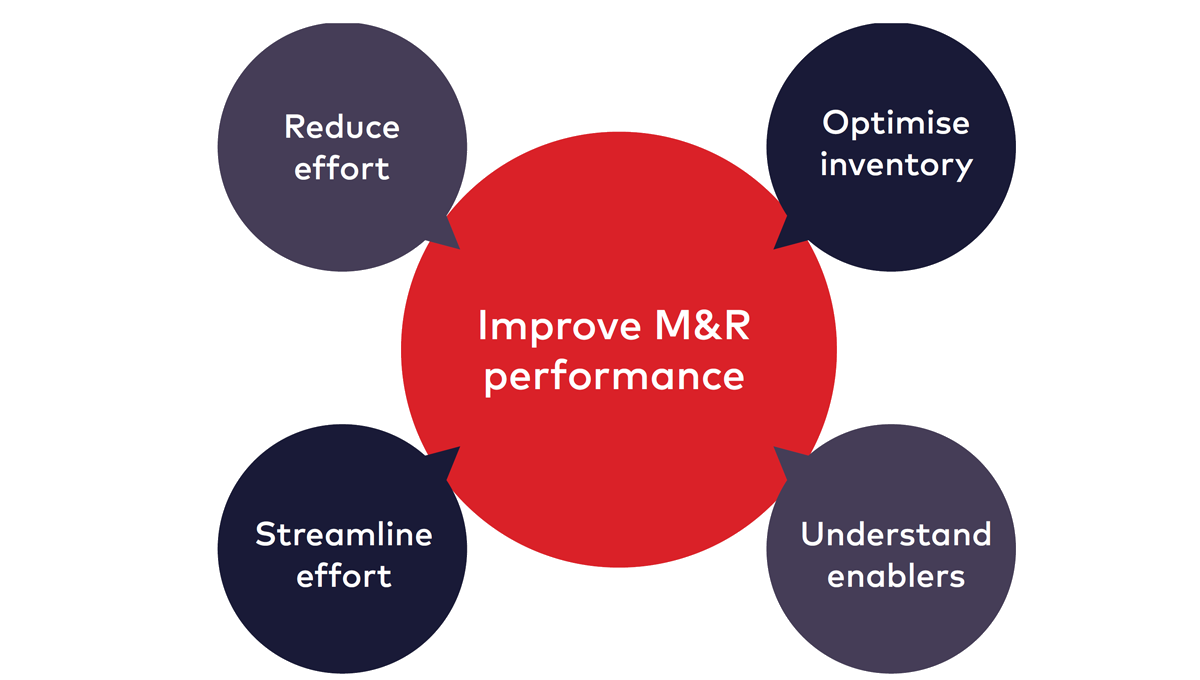

To achieve sustainable transformation, the dss+ approach begins with thorough analyses of the elements that contribute to four primary levers that can be adjusted to optimise M&R activities:

- Reducing the amount of work performed

- Streamlining necessary work

- Optimising spares and inventory

- Understanding key enablers

While each organisation will have a specific set of requirements, the following generally apply across utility companies and provide the bulk of inputs needed to develop sound M&R optimisation strategies.

- Reducing the Amount of Work Performed

Targeted analyses identify opportunities in which work can be safely reduced or eliminated. An asset criticality assessment, for example, guides a risk-based approach to asset management. Digging deeper to identify bad actors and eliminate defects and causes of repeat work release further value.

Finally, crafting the right preventive and corrective maintenance strategy can lead to high asset availability and integrity at optimum cost. - Streamlining Necessary Work

Where work cannot be eliminated, additional assessments seek opportunities in which effort may be minimised. For example, analysis of work orders uncovers areas in which compliance can be increased while reducing manhours and cost. A review of scheduling effectiveness can point to ways to execute more efficiently. Additionally, looking closely at backlogs and their root causes opens the door to defining areas for improvement. - Optimising Spares and Inventory

Managing stock levels and costs represents opportunities to release valuable working capital. For instance, examining maintenance expenses can expose cost drivers, such as how much is being attributed to spares. A deep dive into spare part management will reveal unneeded inventory and potential cost reduction opportunities, and probing spare part criticality and variances can lead to lower carrying costs. - Understanding Key Enablers

Investigating often-ignored support functions and factors is fundamental to achieving meaningful advances in M&R optimisation. Assessment of the operating model, for example, can help overcome barriers to productivity. Reviewing significant metrics may point to ways to boost performance. And utilising industry 4.0 digital tools can maximise efficiency, verify CMMS data quality and guide decisions.

A New Model for Operational Excellence

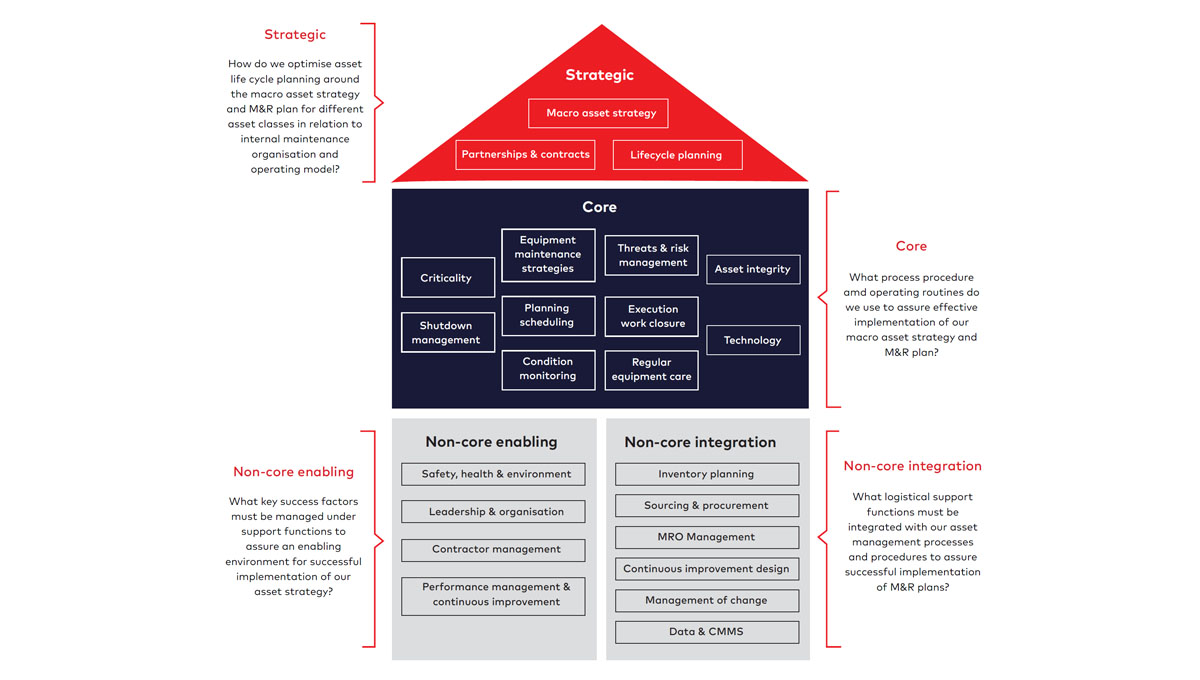

Once potential areas for optimisation have been identified, the dss+ M&R Maturity Assessment Framework lays out a road map for achieving results. This approach is differentiated from traditional M&R frameworks that only consider strategy and core processes.

By contrast, this model achieves the desired future state by pressing further, considering foundational enabling factors and integrations that are vital to continued growth and competitiveness.

Strategic clarity drives decision making This methodology begins with the overall strategy, considering the best approaches to asset life cycle planning, the macro asset strategy for various asset classes, and whether responsibility should reside within the internal organisation or be outsourced. Each of these decisions may give rise to new considerations—for example, if work is to be outsourced, there are potential IP and security risks to discuss, as well as risk ownership and rigorous performance monitoring in order to assure that quality and reliability are not compromised.

Core processes are viewed through a new lens

All traditional M&R processes, procedures and operating routines must be reconsidered in light of assessment findings and new strategic directions.

Technology is likely to require extensive attention, as industry 4.0 solutions impact every aspect of the M&R operation and beyond.

Many areas, including planning and scheduling, equipment care, maintenance strategies, asset integrity and condition monitoring may be greatly enhanced by remote data collection. In addition, shutdown management and maintenance execution may benefit from new, more efficient approaches based on assessment learning. And criticality and risk management can be reviewed to better connect to the company’s renewed strategic aims.

Non-core enablers come into alignment

The dss+ methodology departs from conventional frameworks by continuing further—address non-core enabling factors across the organisation. These success factors are necessary to create an environment in which an implementation can be successful. Careful attention to organisational alignment and governance, for instance, is central to ensuring that processes become routine. No long-term improvement can be achieved without understanding how efforts may impact health and safety. And the communication that flows down from leadership—and back up again from the field—builds ownership and accountability and provides for continual review and improvement.

Non-core integrations embed changes

Finally, addressing areas that don’t typically fall under the M&R umbrella brings logistical support functions on board. These noncore integrations include:

- Inventory planning, sourcing and procurement - In addition to the inventory optimisation advantages already discussed, a robust replacement strategy ensures that as assets age, functional requirements evolve and innovative technologies become available, organisations can plan for and procure the right assets at the right time.

- Change and MRO management, continuous improvement methodologies, and others - All of these functions must be engaged to usher in an evolving transformation with positive, lasting effects.

- Data and CMMS - Continual monitoring of assets and the environment by industry 4.0 technologies provides vast data to support a shift from time- or utilisation-based maintenance and allows quick responses to fault conditions. What’s more, rich, real-time information offers insights into root causes, risk and incident prevention, and ways to optimise grid performance.

Considering the organisation as a whole, rather than M&R as a discrete function, allows necessary performance improvements to become firmly established.

Digital holds the key

The future of utility efficiency, safety and reliability are in advanced technology. Utility companies around the globe are already seeing how industry 4.0 innovations offer tremendous potential for rapid gains and deliver on a wealth of benefits:

- Enhanced asset maintenance strategies – Real-time capture and ongoing monitoring of drone, IoT and sensor data provides insight into asset conditions, the environment and events across a broad geographic footprint. AI and machine learning support ongoing network performance analysis, a shift to predictive maintenance and the identification of fault conditions.

- Improved asset performance – Real-time, integrated asset performance data lays a solid foundation for more informed, strategic models and decisions and provides ongoing quality assurance for work that has been performed.

- Better organised planning and scheduling – Electronic workflows and predictive analytics support predictive maintenance strategies and resource planning, as well as electronic permits to manage compliance requirements.

- More efficient maintenance execution – A connected workforce, remote virtual support and automated processes allow engineers and exploratory drones to relay information quickly to team members for expedient resolutions.

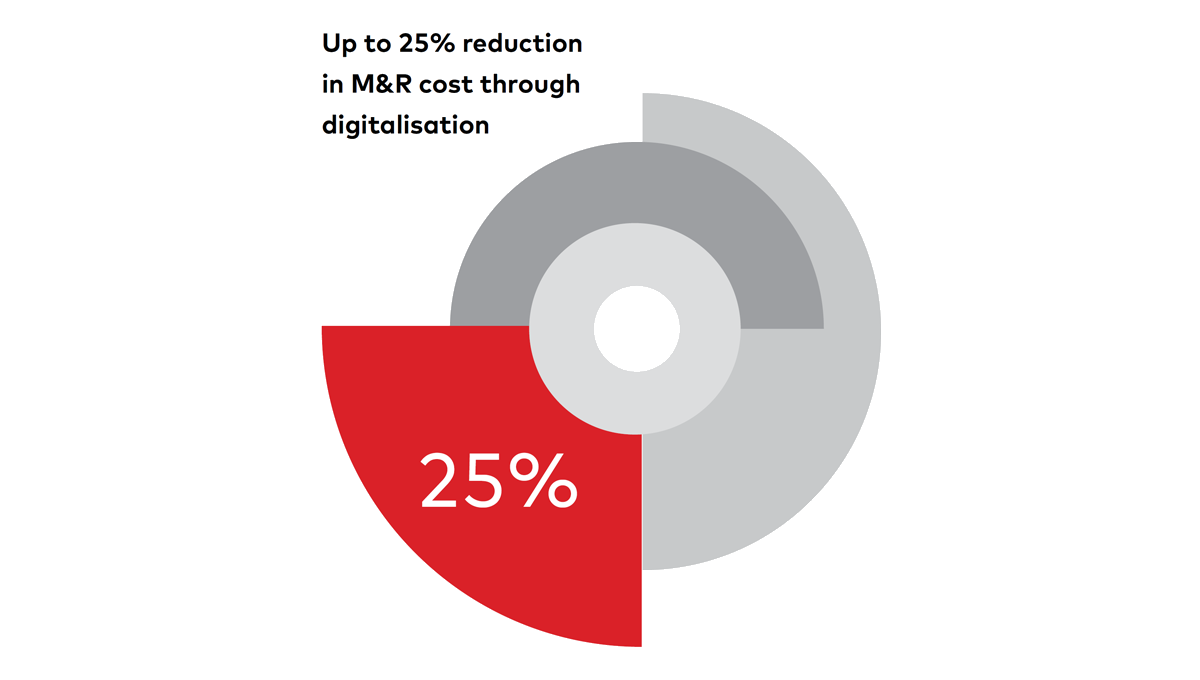

Digital solutions that include predictive analytics, data-driven decision making, a connected workforce and high security can reduce maintenance costs by as much as 25% while improving availability, reliability and decision making.

Achieving M&R Excellence

As power and utility companies seek to maximise asset performance, minimise wasted time and cost, and benefit from innovation, the answer is a comprehensive look at the levers within and outside the realm of traditional maintenance and reliability, as well as an intentional shift toward digital solutions.

As dss+ has worked with organisations to implement new technologies and processes, it has become clear that excellence requires operational discipline and engagement across teams. These are the elements that were the organisation together, creating a cohesive entity that can effectively drive toward shared goals.