Tata Steel

One of the world’s largest steel producers, Tata Steel stands out not just for its size and global presence, but for its humanistic approach to operations. The company’s employee-first attitude is evident in everything they do – particularly in the way they look at safety. A recent Risk Profiling initiative between the Tata Steel - Kalinganagar (TSK) site and dss+ is an excellent example of how this mindset pays back in improved safety, reliability, and resilience. These characteristics allow the organization to more readily deal with dynamic and emerging risks, such as challenges posed by the recent COVID-19 pandemic, as risk thinking is ingrained in every member of every team.

Risk Profiling Turns Deep Shop Floor Experience into Enthusiastic Risk-Based Decision Making

Front-line workers are critical layers of protection, as they are familiar with the organization's activities, equipment, and processes—and, therefore, risks. Leveraging the day-to-day operational knowledge of personnel on the shop floor or in the field is key to success in any cultural transformation.

Having worked with dss+ for years, Tata Steel embraces the perspective that "Safety Is Good Business." That’s why, when they commissioned a new greenfield plant at Kalinganagar, Tata Steel partnered with dss+ in appropriately engaging, empowering, and training their workforce in active operational risk mitigation.

Aligning and inspiring an especially diverse workforce.

As part of their ongoing ambition to become an incident-free organization, Tata Steel had already embarked on a holistic risk management and cultural transformation journey across all of its operations. When the new location was opened, mature safety procedures and best practices were adopted from their existing facilities in India and abroad.

However, it became apparent that processes required customization to suit their local workforce, as well as emerging technologies. The new site was staffed by nearly 8,000 people—many of whom were young and inexperienced. Those who did have previous work experience often came from different industries. To further complicate the situation, a large portion of the workers were contractors, a group that can be difficult for a company to directly influence.

But Tata Steel doesn't differentiate between employees and contractors on the shop floor. Anyone who works in their facilities has the same expectations and responsibilities.

"Contractors are often considered 'outside folks,' not company employees. But an ideal and sustainable safety culture considers contractual employees as 'own employees' with respect to safety. We strongly believe in it and strive to involve our critical mass, including contractors, in our transformation journey."

– ABHINAV SHARMA, PSM SENIOR MANAGER AT TSK STATED IN HIS 2019 CCPS GLOBAL SUMMIT ON PROCESS SAFETY PRESENTATION

To align all levels of the organization and improve capabilities around recognizing and mitigating risk, dss+ recommended a comprehensive Risk Profiling initiative. The program was designed to educate, engage and enthuse thousands of workers in order to:

- Eliminate subjective decision making

- Help all workers recognize the importance of risk identification, reduction and prioritization

- Instill good operating discipline from top to bottom

Risk Profiling: Transforming the way individuals relate to risk.

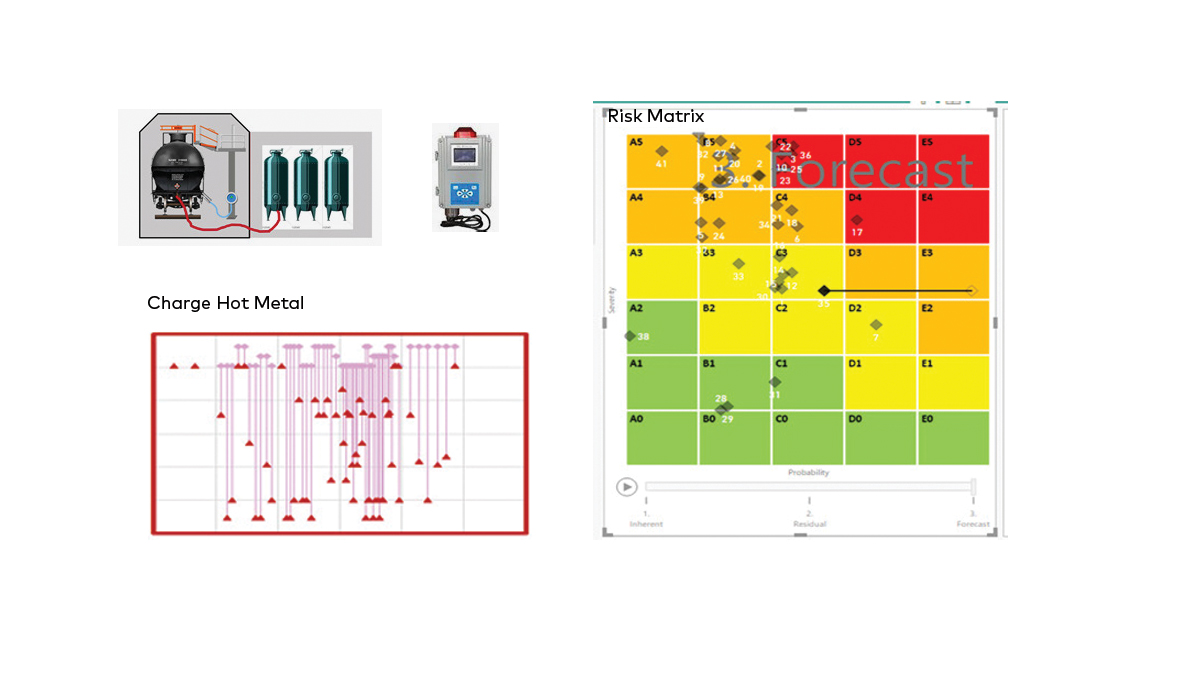

Risk Profiling is a process of collecting, assessing and addressing potential hazards across competency areas and sites from the perspective of asset-facing personnel. Risk Profiling is a transformative approach that aims to change the way people on the ground think about risk. In addition to enabling differential risk treatment decisions, Risk Profiling impact extends across the organization, informing and driving priorities, EHS actions and capability development needs. At the site level, Risk Profiling provides clarity on risks and investments, while at the corporate level, it supports audit plans, investments, leadership action, corporate EHS programs, and asset prioritization.

Risk Profiling is based on the understanding that safety management systems are executed by people. Safety initiatives cannot result in desired outcomes unless the workforce has the right capabilities, mindset, and discipline to properly carry them out, or without processes for managing performance.

Risk Profiling in Action: A Closer Look at the Silo Charging Process

Even though TSK had robust safety procedures for loading materials, structured interactions with operators identified a few unaddressed scenarios with potentially serious or fatal consequences.

- Risk Scenario Identified: Trucks carrying magnesium and lime use nitrogen(N2) gas as a catalyst to pump the mixture through hoses into silos. The workers know that N2 is a hazardous gas, but were not fully aware of its fatal potential, especially in a semi-confined space.

- The silo charging area becomes a semi-confined space once a truck moves into the hub for unloading. If hoses were to leak N2, there would be no way for workers to know.

- As large quantities of lime dust could sometimes be seen in the hub after a truck completed unloading, the team realized that N2 could be released and contained in the hub in much the same way.

Envisaged Solution through Risk Profiling

Through the Risk profiling program, the team discussed the end-to-end process and profiled the various hazards involved and their potential risk scenarios were identified as above. The possible long-term and short-term solutions to reduce/remove/mitigate the risks were also discussed with the operators and documented. These solutions were shared with the leadership team and some of them got adopted. These include:

- Multi-gas detectors with alarms to be fixed in the silo area will alert the operators in case of any potential N2 leaks. N2 threshold limits are displayed prominently in and around the area.

- SOPs are revised to include the risks of N2 gas leakages and preventive and mitigation measures defined in case of a leak at the hub.

- The SILO area hub was recommended for expansion to make it more spacious for any residual N2 gas to quickly disperse out in the open air without affecting the operators around.

Embedding risk thinking across the shop floor.

The Risk Profiling concept was introduced to front-line personnel through hands-on training and discussions in which every process was mapped and analysed. Walking through their days, operators shared risks they had already identified as well as others that might arise. For each risk scenario identified, they gauged consequences, estimated annual exposures, and collaborated on potential solutions.

Over time, this novel approach fostered tremendous engagement, as workers began to envision themselves as a critical layer of protection within the organization. At the same time, TSK was able to collect real-life experiences, learn from dynamic information, perform analytic,s and facilitate data-based risk management decisions.

As they participated in these sometimes-intense debates, engineers and management were often surprised by perceptions of risk that traditional registers and SOPs would never have identified. Giving employees a structured way in which to speak up about the operational risks they face on a daily basis helped TSK close numerous gaps in their safety processes. What’s more, as workers began to own safety risks, their awareness of business risks grew, too. They began to pinpoint threats such as potential asset damage, equipment failures, environmental non-compliance, and business disruptions. As a result, production cycles have been improved and unscheduled maintenance has been reduced.

Clear benefits gained by focusing on hearts, minds and trust.

Rather than trying to compel workers to merely follow procedures as they're written, TSK took a unique track, targeting workers' hearts and minds and handing the reins to those on the front lines. As workers grew to understand the value of their participation in the TSK safety culture transformation and how their contributions helped protect their own welfare, they developed deep trust and ownership in the process and the company.

Working together to eliminate risk wherever possible, Risk Profiling methods gave everyone the space and confidence to open up about experiences and perceptions that might otherwise be ignored or downplayed, leading to safer work practices, greater operational discipline, and more attuned perceptions of risk. This culture of risk thinking is a critical link between safety and good business.

Risk Profiling has reached a broad cross-section of workers at the TSK plant and has had important impacts on their industry-leading procedures:

- Over 70% of the workers (areas where Risk Profiling was deployed) have participated in Risk Profiling training, structured interactions, and other activities that build capability and competency while reducing anxiety and increasing confidence.

- More than 600 risk scenarios have been identified and validated, providing management a solid basis on which to prioritize solutions and utilize resources for the greatest impact. Recommendations such as strengthening SOPs for rigour, improving operational discipline, reviewing or reinforcing barriers, and enhancing communication have been developed and are being implemented.

- More than 40% of the SOPs have been revised and strengthened in the areas covered under this program. Because workers themselves helped identify the problems and craft the solutions, buy-in is internal and operational discipline is enhanced. Approximately 10% of the processes have benefited from automation or digitalization to reduce risk, and all of the potentially highest-risk items have been addressed.

- There is now openness and enthusiasm among operators to discuss, report and correct anything unusual in their work areas.

- Vibrant management systems have moved the company’s approach away from forced agreements and compulsion toward a culture of shared, ingrained belief among all levels of the organization.

"In just a short time, the company's culture has undergone a significant shift—vast numbers of disconnected personnel have been visibly transformed into a vocal, confident, risk-aware workforce running a safe, reliable operation. There is now openness and enthusiasm among operators to discuss, report and correct anything unusual in their work areas."

MR. BIBHUDUTTA MOHANTY, CHIEF OF SAFETY AT TATA STEEL - KALINGANAGAR SITE

Structured interactions and interviews encourage teams to think beyond their immediate safety concerns to consider potential asset damage, equipment failures, operational disruptions, environmental non-compliance, and other business challenges as risk outcomes. While workers know that hazards cannot be 100% eliminated, they have trust in the process and are enthusiastic about their roles in appreciating and reducing risks every day.