Embracing the Green Hydrogen Transformation in Mining

As the mining industry strives to decarbonise, companies are rapidly adopting new technologies to enable the energy transition. One technology with enormous potential is hydrogen (particularly green hydrogen), which is expected to generate substantial greenhouse gas (GHG) reduction benefits and business opportunities.

Over the next few decades, hydrogen is predicted to play a key role in energy transition and decarbonisation across various industries. It is estimated that it will account for 12% to 20% of energy demand in 2050.

Hydrogen is Already a Reality in Mining

To successfully shift to a renewable energy system that includes hydrogen, mining companies must undergo a holistic business transformation. When properly planned and implemented, though, mining companies can produce a meaningful and environmentally friendly change in the industry.

For example, in mining operations, the adoption of green hydrogen can reduce GHG emissions by replacing diesel fuel in hauling vehicles, which can contribute 30% to 80% of a mine’s emissions footprint. Other benefits include the removal of diesel particulates and the reduction of ventilation load requirements in underground mining.1

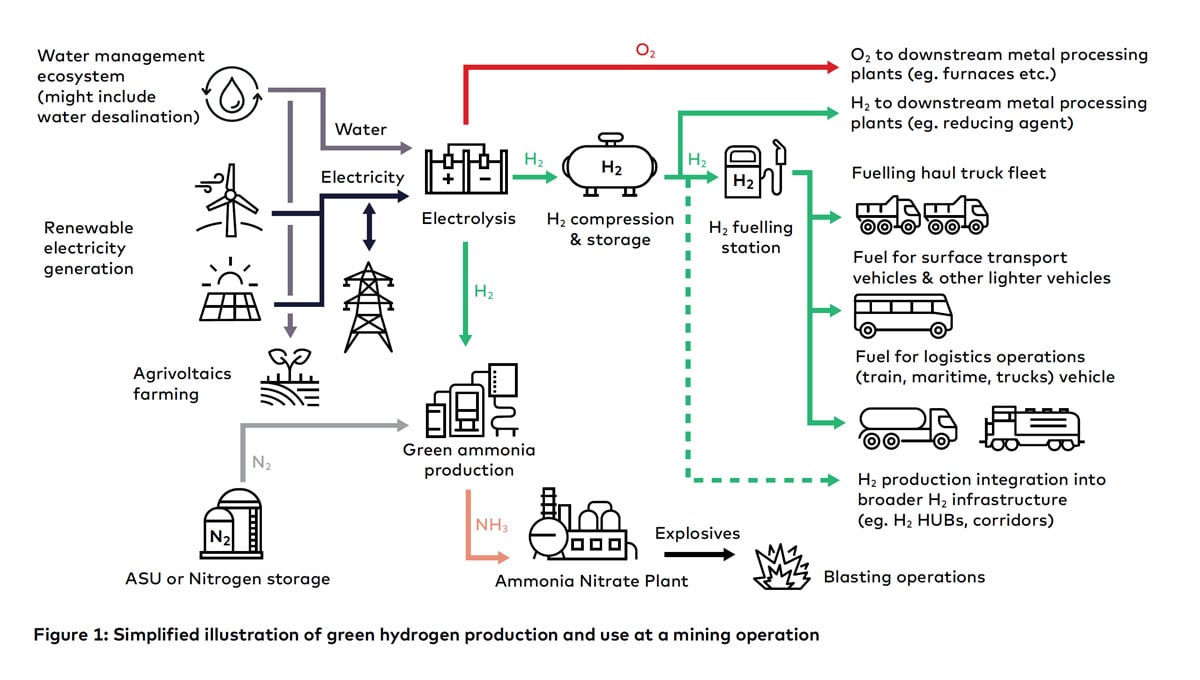

A broader transformation of energy systems in the mining industry has already begun, with hydrogen has a key tactic. Indeed, numerous mining companies are actively exploring and driving a range of initiatives to adopt green hydrogen in their energy mix as well as a new source of business (Figure 1), for example:

- Production of green hydrogen and use as fuel substitution in a range of heavy mining vehicles and equipment;

- Reduction of carbon footprint of produced minerals and metals to meet low carbon requirements in downstream processing operations (e.g. low carbon/ green steel);

- Evolution/expansion of business model beyond minerals and metals production into green energy generation;

- Strategic partnerships and alliances aiming to influence, support and fuel investments, technology advancements and grasping broader business opportunities that are offered by the energy transition and decarbonisation.

At Anglo American, for example, the plan is to convert its diesel-powered haul trucks to green hydrogen-powered trucks across numerous operations. FMG is driving the development of green H2 production facilities across a number of locations. Freeport-McMoRan also is planning to transition its fleet of diesel trucks and other machineries to electric or hydrogen power. BHP is partnering with leading steel manufacturers to investigate alternative hydrogen use in steelmaking. Many other mining players are exploring various options for hydrogen adoption.

Scaling Green Hydrogen in Mining Operations

While hydrogen and its hazardous properties are not new, hydrogen has yet to be used at scale in the mining industry. As such, there is risk.

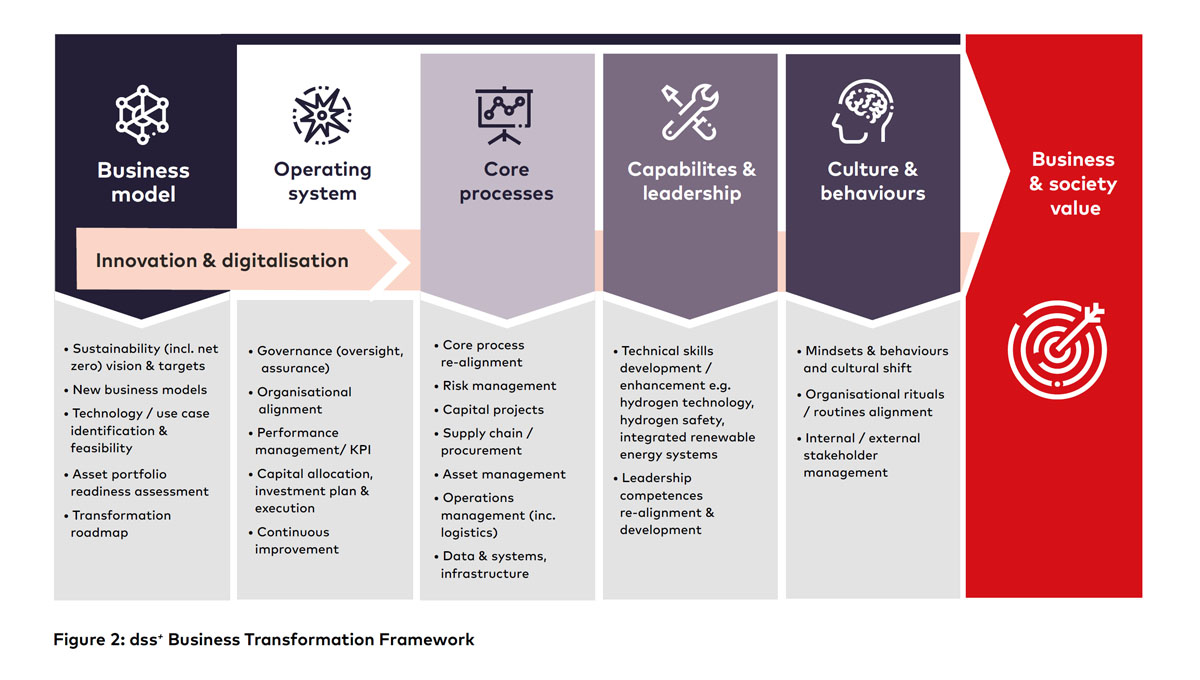

To reap the potential benefits and opportunities green hydrogen can present, businesses must develop a holistic appreciation of the risk factors, operational challenges and sustainability implications that can affect large-scale deployment. This goes far beyond the technicality of designing and building hydrogen production facilities or converting an entire truck fleet. A holistic business and operational transformation is paramount – one that encompasses the evolution of business and operating models, the realignment of core processes, the successful deployment of new technologies, the building the necessary organisational capabilities – whether internally or with new partners – and ensuring of the right mindsets and behaviours are in place to sustain the transformation (Figure 2).

In addition to necessary changes in the regulatory environment, policies, external energy infrastructure, we at dss+ believe there are five key operational aspects that underpin the successful deployment of green hydrogen at scale in mining operations:

Change in Risk Profile

The introduction of large quantities of hydrogen may increase exposure to unwanted events such as fires, explosions and arc flash. A thorough review of operational risk management, asset integrity and reliability programmes is necessary. Risk reduction is dependent on effective design, material selection and engineering controls.

Technology Readiness and Innovation Portfolio Management

There has been a steep increase in the research and development of new hydrogen-related technologies in recent years. It is expected that these technologies will continue to evolve quickly, and there will be pressure to ramp up fast. The level of readiness, therefore, will be variable and pose uncertainties with the viability of the technology, cost, safety and efficiency in large applications at scale. A rigorous technology development and deployment process can offset cost and performance uncertainties. Developing a portfolio of products and solutions can help achieving the transformation goals.

Capital Projects

Green hydrogen is still very expensive to produce and reducing cost is critical to enable adoption at scale. Concurrently, large capital projects are exposed to a wide range of uncertainties and risks that project managers need to deal with to bring their ongoing and future projects within budget and time, while meeting increasingly stringent sustainability expectations. Therefore, scaling hydrogen in mining must involve planning and executing a range of different projects under an overarching programme management umbrella. In this regard, depending on the type of projects and the level of project risk, the basket of projects should be managed with combining the “traditional waterfall” and “agile” approaches to achieve better outcomes throughout the journey.

Asset Integrity and Reliability

It takes a high level of operational discipline to safely produce and handle hydrogen across the entire asset lifecycle. The critical control management programmes commonly adopted in the mining industry are not sufficient to manage the change in operational risk profile. Specific failure modes in equipment handling hydrogen call for a thorough enhancement of asset integrity and reliability strategies and programmes. More thorough process hazard analysis, specialist process safety in-design knowledge in the engineering and design phases, as well as quality assurance during fabrication and installation stages, are of critical importance for hydrogen technologies.

Partners and Suppliers

Because the hydrogen value chain is still in its infancy, the process will necessitate a collaborative approach. The right partnerships are paramount and will create critical mass, cut costs and improve manpower.

In sum, the complexity of scaling hydrogen in mining should not be underestimated. Adopting a holistic and integrated approach is of paramount importance to the safe, reliable and effective adoption of new technologies and systems.

Once companies appreciate the significant change in risk profile and potential new business opportunities, they are better prepared to activate their green hydrogen journey. The orchestration of the journey will require a transformative approach with strong emphasis on building organisational capacity, new capabilities and a mature engagement and collaboration with partners and a broader set of players in the supply chain and business ecosystem.

To learn more, please refer to the more detailed white paper that we have produced on this topic, which can be found at www.consultdss.com.

Download Full White Paper

SOURCE:

- ourworldindata.org, Hannah Ritchie and Max Roser, “Emissions by Sector”