BFRs' Impact on WEEE Plastics Recycling - Report

dss+ has recently completed a study commissioned by BSEF - the International Bromine Council, which provides key insights into recent developments in the composition of WEEE plastics, brominated flame retardant content, regulatory context and technological advances.

Waste electrical and electronic equipment (WEEE), also known as e-waste, contains a wide range of materials. Plastics account for about 25% of WEEE and consist of different polymers (mainly ABS, PP, PS and PC-ABS), which may contain different additives such as flame retardants (typically brominated or phosphorated), mineral fillers, pigments and stabilisers. In Europe alone, WEEE plastics represent a potential volume of approximately 2.6 million tonnes per year. Plastics found in WEEE are often engineering polymers, which are types of plastic materials that are very durable and robust and therefore have a high market value and good theoretical recyclability. In reality, only a small part of the recycling potential is realised today. Indeed, the way in which WEEE and its plastics are managed is characterised by numerous losses along the value chain.

The aim of this study was to provide a comprehensive overview of the current state of WEEE plastics recycling in Europe and to identify opportunities for improvement, with a focus on the role of brominated flame retardants (BFRs). In particular, the study aimed to:

- Provide updated figures on the composition and fate of WEEE plastics: In particular, trends in BFR content and the current recycling capacity of WEEE plastics in Europe.

- Discuss technological and regulatory developments regarding the management of WEEE plastics containing BFRs.

- Assess the potential of emerging technologies such as solvent-based recycling, pyrolysis or depolymerisation for the treatment of difficult-to-recycle plastics from WEEE.

- Identify the challenges and opportunities associated with the incorporation of recycled plastics into new electrical and electronic equipment.

Key findings:

BFR Levels in WEEE Plastics:

- Overall, levels of restricted BFRs continue to decline in WEEE plastic streams. The average share of PBDEs in the total bromine content has decreased from above 20% in 2015-2016 to below 10% in 2021-2022. However, occasional high PBDE levels may still be found in WEEE streams due to the presence of older devices manufactured before regulatory restrictions were in place.

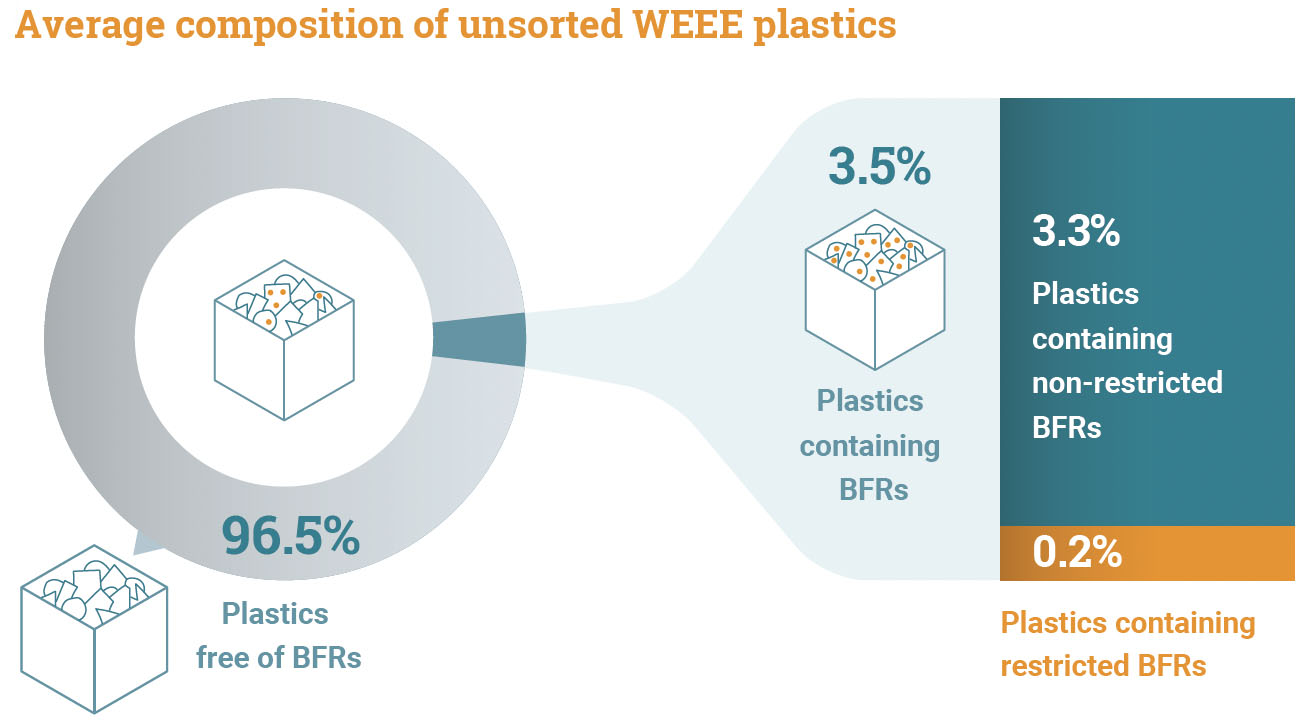

- WEEE plastics contain an average of 3.5% BFR-containing plastics, including 0.2% of PBDE-containing plastics and 3.2% of non-restricted BFRs. The proportion of brominated plastics varies across categories, with screens and small equipment containing around 7-8% of brominated plastics, while large equipment and cooling appliances contain much lower proportions

Fate of WEEE Plastics in Europe:

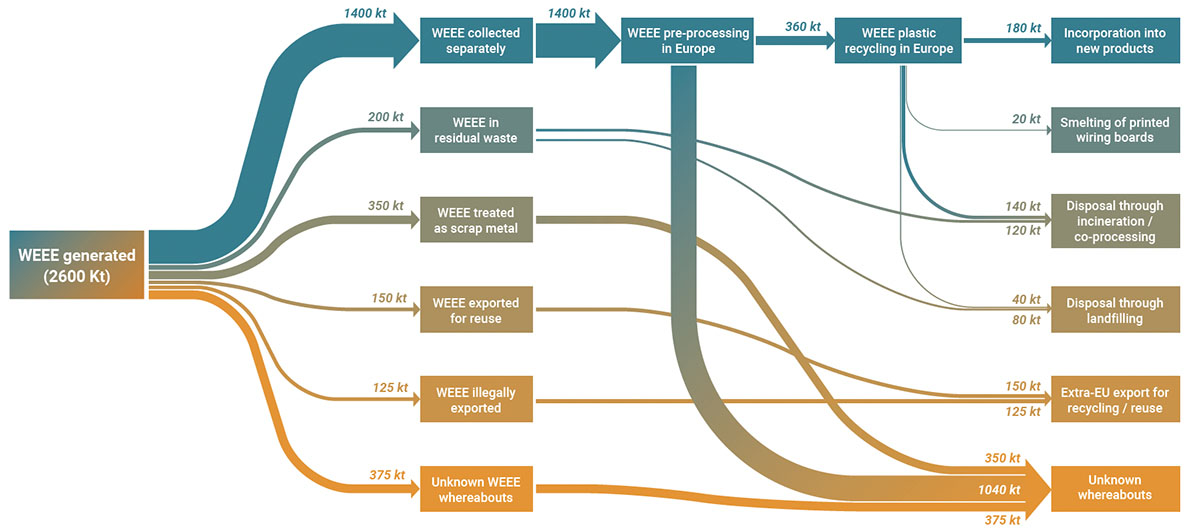

- In 2021, Europe generated approximately 2.6 million tonnes of WEEE plastics, but only 54% (1.4 million tonnes) were collected through official WEEE channels. Out of the collected amount, only 0.4 million tonnes reached specialised WEEE plastic recycling companies in Europe (15% of total).

- Around 46% of all WEEE plastics manage to evade official collection. Some are treated as scrap metal or disposed of with mixed waste, while others are exported outside Europe, legally or illegally. When considering the final destinations of all WEEE plastics arising in Europe, 68% have an unknown fate, raising concerns about unsafe recycling practices or improper disposal. This includes WEEE plastics escaping formal WEEE collection, as well as leakages in official WEEE treatment channels.

- Europe has more than 40 companies specialising in WEEE plastics sorting and recycling, with an estimated combined capacity of around 800,000 tonnes per year. However, this total may include some double counting, as different companies may be involved in different steps of the supply chain, e.g. some companies may only carry out pre-sorting, others only final sorting and compounding.

Regulatory Developments:

- Proposed changes in regulatory threshold for wastes (LPCL) and products (UTC) containing restricted BFRs (HBCD and PBDEs) will pose significant challenges to WEEE plastics recycling, due to the lack of reliable sampling, sample preparation and analytical methods to measure BFR concentrations below 1,000 ppm in heterogeneous materials.

- Proposed changes in waste shipments regulations may impact the proper management of WEEE plastics. Increased costs and administrative burdens related to the movement of waste could potentially hinder the recycling of WEEE plastics and create challenges for cross-border waste trade.

- These new regulatory developments pose challenges and increased costs for the movement of waste, making it increasingly difficult for state-of-the-art recycling facilities within the EU to receive and recycle WEEE plastics. The recycling industry has raised concerns about these complicated and expensive regulations, impacting the proper management of WEEE plastics and, ultimately, pushing WEEE plastics towards unofficial channels such as illegal exports.

Conventional and Emerging Technologies for Handling WEEE Plastics:

- At specialised WEEE recycling facilities, plastics undergo a series of sorting steps based on density, electrostatic properties, infrared spectra and/or other sensor-based techniques. Overall, about 50-60% of the input is transformed into secondary plastics fed into the market. The rest, made of a complex mixture of non-target polymers and additives, is currently considered non-recyclable and is sent for disposal.

- Various emerging technologies, such as solvent-based recycling, pyrolysis, or depolymerisation, may offer alternative approaches for handling hard-to-recycle WEEE plastics. There are technical and economical challenges to their widespread implementation. Although they may work effectively for pre-sorted polymers, challenges for their use include the need for optimised process conditions, cost-effectiveness, scaling up the technology, and ensuring compatibility with existing recycling infrastructure.

Recommendations

- Strengthen collection systems: Increasing the separate collection of WEEE would have the largest impact in regard to the correct disposal of BFRs. This can be achieved through effective awareness campaigns, convenient collection points, and mandatory collection targets, allowing for enhanced cooperation between stakeholders to prevent illegal exports and ensure proper recycling processes.

- Harmonise regulations on BFRs, including PBDEs and HBCD, at the international level to facilitate consistent practices and avoid conflicting requirements. Consider the practicality of UTC levels and the availability of reliable analytical methods.

- Promote technological advancements: Encourage research and development in solvent-based recycling and chemical recycling technologies to improve their efficiency, scalability, and cost-effectiveness. Support pilot projects and collaborations between industry and academia, including through reducing constraints posed by intellectual property.

- Enhance data collection: Establish a standardised and centralised database to collect and analyse data on the composition, fate, and recycling capacity of WEEE plastics. This will provide a better understanding of the current state and support evidence-based decision-making.

- Encourage circular economy practices: Promote the use of recycled plastics from WEEE in the manufacturing of new Electrical and Electronic Equipment (EEE). Facilitate collaboration between WEEE recyclers and EEE manufacturers to overcome technical and logistical challenges.

Conclusion

Improving the state of WEEE plastics recycling in Europe requires a comprehensive approach that addresses collection, sorting, regulatory frameworks, and technological advancements. By implementing the recommended measures, Europe can enhance resource utilisation, minimise environmental impact, and move closer to achieving a circular economy for WEEE plastics. It is important to remember that the WEEE plastics recycling industry and its processes only emerged during the last fifteen years and are, therefore, still relatively undeveloped compared to other material recycling, such as the metal recycling processes. To attain the same level of development and achieve the implementation of these recommendations, continued collaboration and knowledge-sharing among stakeholders is crucial.