Transmission Auction

Driving safe, productive and sustainable company and contractor performance

Further to the first Transmission Auction held in 2024, at the São Paulo Stock Exchange, CEOs are faced with a unique opportunity to redefine the future of the energy sector in Brazil.

With 15 lots auctioned, representing an estimated investments of R$ 18.2 billion, the auction reinforces the trajectory of continuous success of transmission auctions since 2017. The implementation of these projects, totaling 6,464 km of transmission lines and 9,200 MVA in transformation capacity, promises to generate approximately 35,000 jobs, highlighting the economic and social relevance of these initiatives.

In this context, the challenge for the leaders of the concession-holders transcends the technical execution of the projects. Operators will face the complexity of working in unfamiliar environments characterized by difficult-to-access territory, low density populations with limited capacity to retain trained labor and extreme weather events that are increasing in frequency. These risk factors are amplified by the pressure imposed at auction on bidders to submit discounted prices to successfully win the work. Leading Power and Utility companies' executives do indeed have a unique opportunity to redefine the future of the energy sector in Brazil by including sustainability as a core principle of future projects and building resilience into their operations to manage such challenges and the existing risk profile of each asset and project.

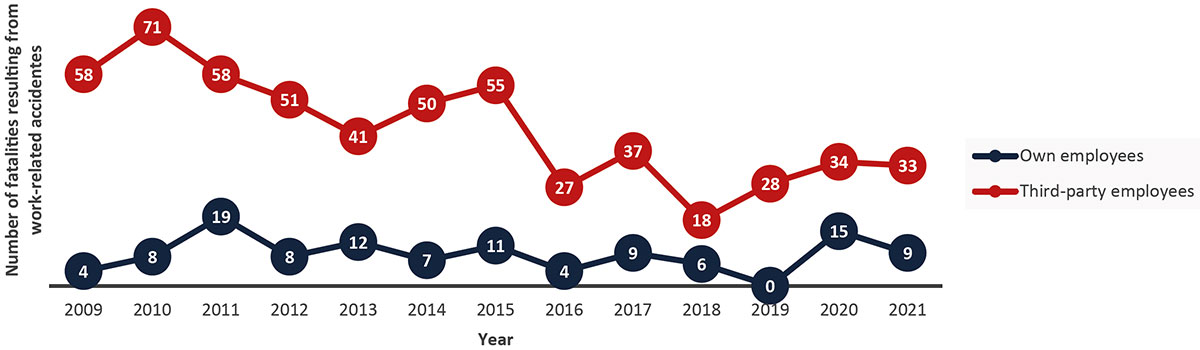

Historically, the transmission line construction and maintenance industry has faced significant challenges related to occupational safety, with incidents resulting in injuries and, unfortunately, fatalities. Each incident reinforces the pressing need to integrate more rigorous safety practices and cultivate an unwavering safety culture at all levels of the organization. Proactive risk management and the implementation of advanced safety technologies are indispensable for preventing accidents and protecting lives.

Recent auctions, which emphasise operational efficiency and competitive costs, should not compromise safety measures. On the contrary, they should serve as catalysts for innovation and continuous improvement in safety practices, because we know safety and productivity have a direct correlation. Concession-holders are now faced with the critical task of balancing efficiency and financial sustainability with the imperative prioritisation of worker safety and environmental protection. These are not contraditory, but suplementary, objectives.

Considering this, we propose an integrated, risk-based approach, recognizing the interconnection between safety, sustainability, and operational excellence as essential components of a comprehensive business strategy. This vision demands an evolution from siloed risk management to a more integrated model, capable of extracting insights from across the organisation to mitigate risks and generate value effectively.

Key considerations for decision-makers:

It's important to reflect on the ecosystem of each asset, in terms of the interconnectivity and interdependence between the company and 3rd parties involved in delivering the auction objectives, including up to those that will benefit from the new transmission infrastructure.

These partnerships will be exposed and tested to respond to both planned and unplanned challenges during the development, pre commissioning and post commissioning into operations. Seemingly unconnected parts of the utility stakeholder ecosystem will by virtue of this interdependence be affected by the inability of certain partners to deliver to scope, be it on quality, time or budget.

The potential impact of these risks may manifest in series or may even be amplified in parallel. An example of sequential risk involves equipment: the design and quality of the equipment itself will only matter in so far as it's properly installed. In turn, it will only fulfill its function if it's properly maintained over the long term.

Contrators will be exposed and tested to respond to both planned and unplanned challenges.

It is therefore imperative that quality control and documentation accompany both the activity in question and the handover to the next partner in the ecosystem. Failure to consistently apply quality and safety controls will not only materially impact budget and timelines of the program but will ultimately represent a risk to other stakeholder such as communities, customers and industries that will rely on the power supplied by the infrastructure.

Weather events should also for example be considered during the planning process, as they can impact supply chain partners, access to site, create hazardous work conditions - disrupting activity to the detriment of the overall program.

The range of new infrastructure will be heavily reliant on contractors during the construction and commissioning phase, and many new ones will be brought in once operation have started - yet the ultimate responsibility rests with the owner as any major issue will ultimately impact them. Managing a workforce with varying capabilities in remote locations, where risks are amplified, requires a partner with a deep understanding of local conditions. This partner must introduce and sustain an organizational culture and procedures that promote a safer and more efficient delivery in the field, starting with the elimination of Serious Injury and Fatality (SIF), and here we see a significant opportunity for improvement, as shown by the numbers reported in the figure 1 below.

In the transmission line construction sector, where there are a limited number of service providers and high labor turnover, the training of leaders across the entire supply ecosystem becomes a critical factor. dss+ advocates investing in the leadership development of these companies, as this will lead to a robust culture in each market niche, with an emphasis on safe and effective performance. This ensures new workers are quickly integrated and aligned with high operational standards, perpetuating a culture of excellence and safety in an environment of constant personnel flow.

Concession-holders must proactively incorporate stringent risk planning and protocols, an effective operating model which includes your contractor workforce and broader ecosystem, as well as environmental factors, into their planning. An acute understanding of Brazil's local conditions is also a must.

It is proven that contracted workers have higher accident rates than employees and are often performing high-risk tasks.

https://dadosabertos.aneel.gov.br/dataset/seguranca-do-trabalho-e-das-instalacoes

By adopting an integrated risk management approach, companies are proactively preparing for future negative events. Through the implementation of rigorous selection, training, and supervision processes, they can significantly reduce the risk of accidents and operational failures.

Equally important is promoting a culture of safety and collaboration, as this will lead to strengthened response in case of emergencies and crises - and of course fewer incidents. Respond to emergencies and crises, ensuring robust organisational resilience.

This approach results in tangible benefits such as cost reduction, increased productivity, and improved company reputation. By investing in the safety and well-being of their third parties and employees, companies are building a solid foundation for future success, even in the face of unforeseen challenges.

Integrated management also aligns with the principles of operational excellence, seeking not only to minimise risks, but also to optimise operational performance. A Contractor Management Systems (CMS), for example, enable a structured approach to managing all phases of the contractor lifecycle, from selection to post-service evaluation.

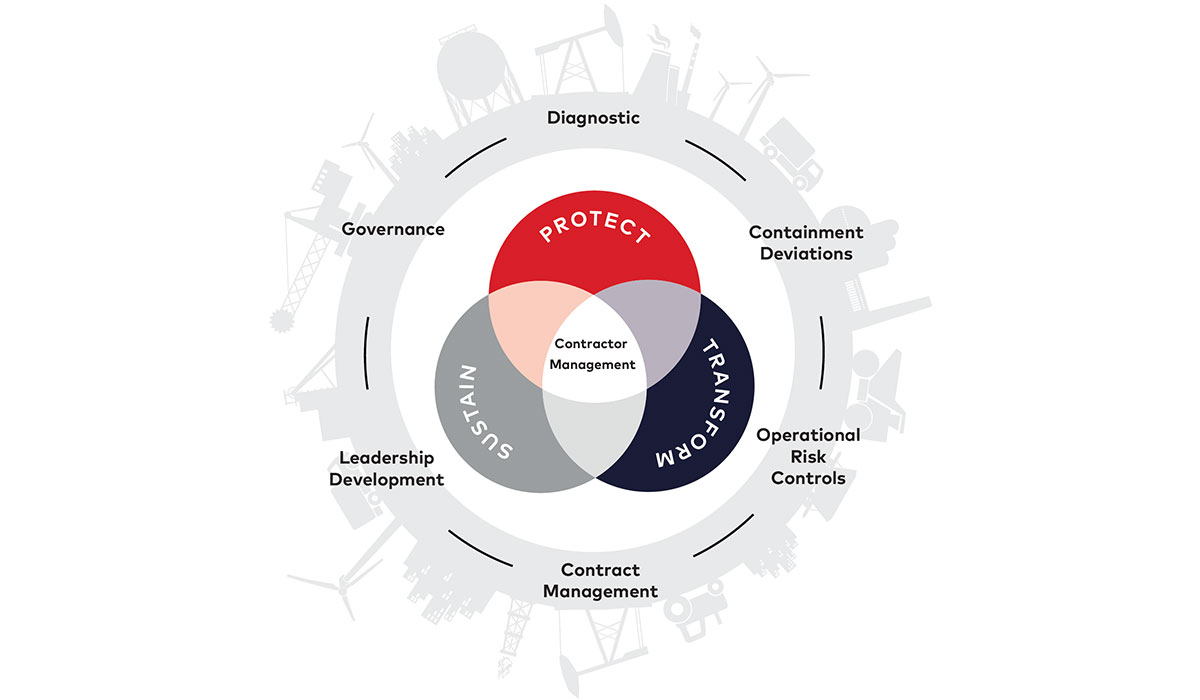

dss+ has developed a specific framework to meet the demands of the energy sector regarding the performance and safety of contracted companies. This framework helps companies adopt an integrated approach to risk management and operational excellence.

© 2024 DSS Sustainable Solutions Switzerland SA.

Proactively managing your contractors

As depicted in figure 2, six interconnected issues should be planned for and addressed concurrently to drive the performance of your contractors in line with your expectations. Six processes that, when applied together, directly address the root cause of the problem. It starts with a detailed diagnosis of contractors that includes rigorous human rights due diligence. Subsequently, act on two simultaneous fronts: one focused on containing deviations, with an emphasis on serious Injuries and Fatalities (SIF), and another deeply analysing the controls of critical operational risks. Finally, review governance processes, contractor management, and heavily investing in the leadership development of both internal and contracted companies, with the goal of establishing a cohesive and aligned culture.

This framework can be suported by a centralized digital platform for storing and managing important information, such as certifications, training, safety records, and past contractor performance. Additionally, it can facilitate communication between different departments involved in third-party management, ensuring effective collaboration and informed decision-making.

Sustainability has become an increasingly important issue for companies worldwide, especially in the energy sector. With growing concerns over climate change, social issues, and the scarcity of natural resources, companies in this sector are seeking ways to embed sustainability at the core of their operations, and this process must include their contractors. Our experience shows that sustainability initiatives will be regarded as value drivers, rather than cost centres, when environmental and social considerations are tackled holistically with the company's economic and operational goals in mind. Here, we highlight three examples.

Engaging local communities

In transmission line projects that pass-through areas inhabited by local communities, the training and engagement of these communities not only support the social aspect of sustainability, but also minimise the risk of operational interruptions due to protests or litigation. A focus on social sustainability ensures that communities not only endorse, but also benefit from the project through employment and development. In Brazil, where social and environmental challenges are as prevalent as the opportunities, developing strategic partnerships with contractors who share this vision of sustainability is crucial. It’s not just about avoiding costs or penalties; it's about creating tangible and intangible value, both for the companies and for the communities and the environment.

Reputation and Branding

The human rights due diligence approach for the construction of transmission lines aims to mitigate risks of violations, protect all parties' reputation, and strengthen brands. This involves assessing impacts, engaging stakeholders, establishing internal policies, vetting third parties, communicating transparently, and offering remediation mechanisms. These practices demonstrate a commitment to human rights and contribute to the sustainable development of communities. Bidders that have successfully been chosen to build and operate the next generation of transmission capability in Brazil, now have the opportunity to play a leading role in building generational wealth for the country. Putting sustainability at the heart of execution plans will have a cascading impact on the environments and communities that they will be working alongside.

Energy efficiency

With careful consideration during the planning phase, the building, commissioning and ongoing operation of the asset will be delivered against the minimum energy requirements. This will generate a double benefit: minimising expenditure and a minimised carbon outcome.

Recently, a dss+ team identified 20ktCO2e emissions potential reduction by 2030 for an infrastructure company, at the the lowest marginal cost of abatement.

© 2024 DSS Sustainable Solutions Switzerland SA.

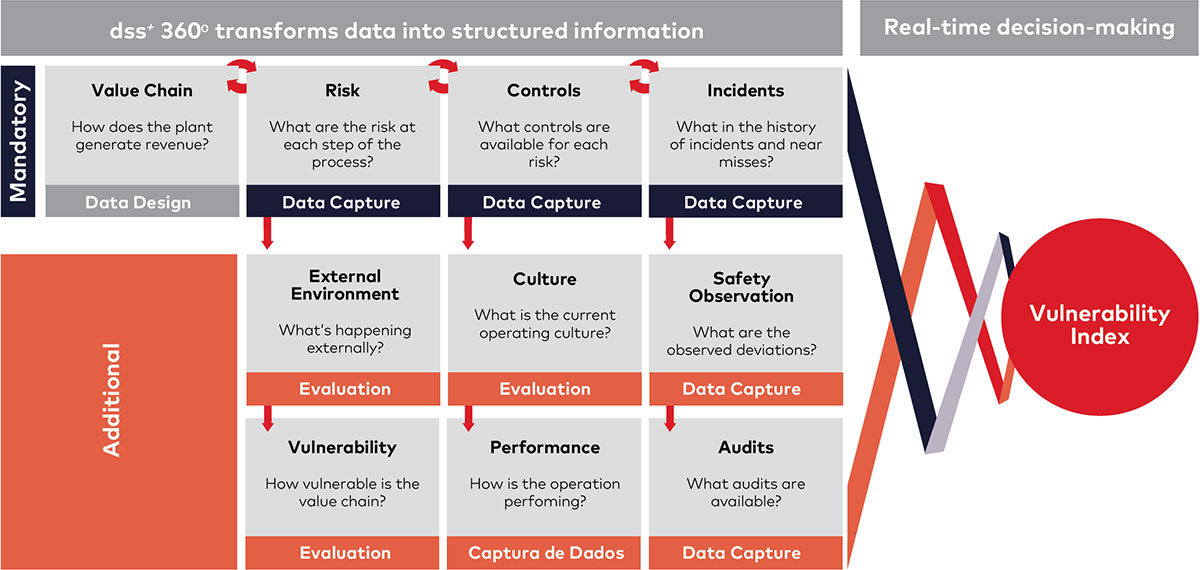

In addressing the management of contractors for transmission lines projects, organizations face the challenge of effectively leveraging vast and often unstructured data generated at various stages of these projects. This data, encompassing contractor performance metrics, safety records, environmental impact assessments, and compliance documentation, is crucial for strategic contractor management.

Traditionally, the disparate nature of this data has led to its underutilization, presenting a barrier to operational excellence and sustainability.

AI's Role in Shaping a 360-Degree Operational Perspective

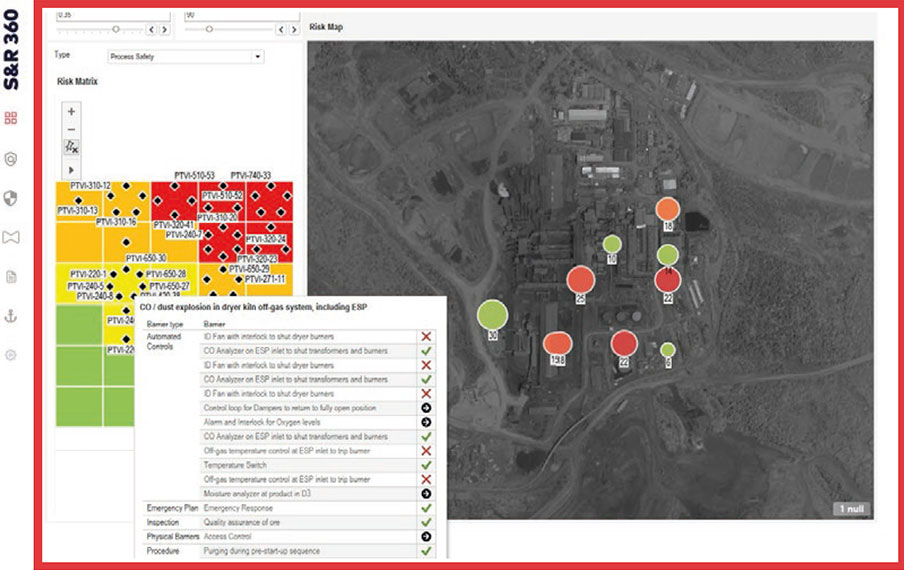

The incorporation of AI offers a 360-degree perspective on operations and gives executives an exhaustive understanding of the contractor landscape.

The unique capability of AI in categorising and transforming unstructured data into actionable insights provides an overarching operational visibility, bridging seemingly siloed data points.

© 2024 DSS Sustainable Solutions Switzerland SA.

dss+ Approach

dss+ Approach With a robust database compiled from our experience across a variety of companies and sectors, we can offer valuable insights and deep analysis based on concrete information.

Specifically, within the transmission ecosystem, our system adeptly processes diverse datasets to generate comprehensive performance and risk profiles for each contractor, incorporating a nuanced appraisal of performance, reliability, and risk, moving beyond the conventional cost-centric focus.

© 2024 DSS Sustainable Solutions Switzerland SA.

- Leveraging sophisticated algorithms, dss+ 360 excels in unveiling patterns, trends, correlations, and anomalies within the complex fabric of operational risks, accurately estimating the probability and impact of these risks in contractor management.

- Machine Learning algorithms are instrumental in real-time monitoring of compliance with safety and environmental standards, ensuring that projects remain within regulatory confines. This continuous oversight minimizes the risk of penalties and interruptions, bolstering project integrity.

- By incorporating human expertise, the approach validates and complements the results obtained, defining effective strategies for risk mitigation and prevention, considering technical, economic, social, and regulatory aspects.

Authors